Features:

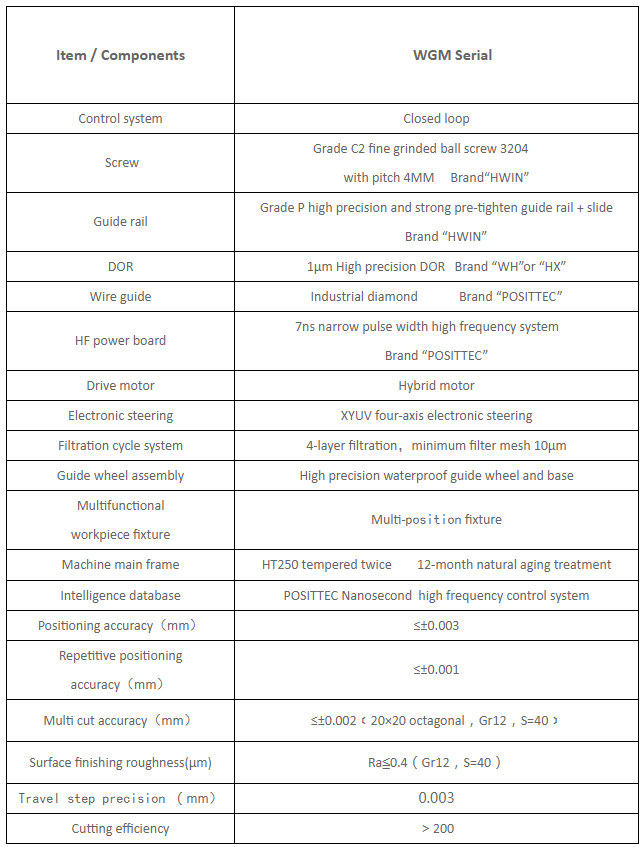

■High precision: Cutting precision up to ±0.002mm. Most stable and precise linear guide and ball screws from the top manufacturer; solid casting frame to ensure the consistence and durability.

■Fine Surface Finishing: Ra≤0.4μm without defects (cut once and refine twice). Multiple cutting function: Available to perform refine cutting. Ra≤0.47μm with extra thick metal.

■High efficiency: Consistent cutting speed over 200mm²/min. Max cutting speed up to 400mm²/min. The unique impulse power supply makes less worn-out or broken of wire.

■Simple & Safety: Multi-function fixtures make it easier for parts with different profile. Less change over.

Modular designed power and control system makes the operation and maintenance much easier with better consistence than similar machines. UVXY steering control.

Moly wire at consistent tension from start to end. Spray intelligence controlled without jam.

Innovated Technology:

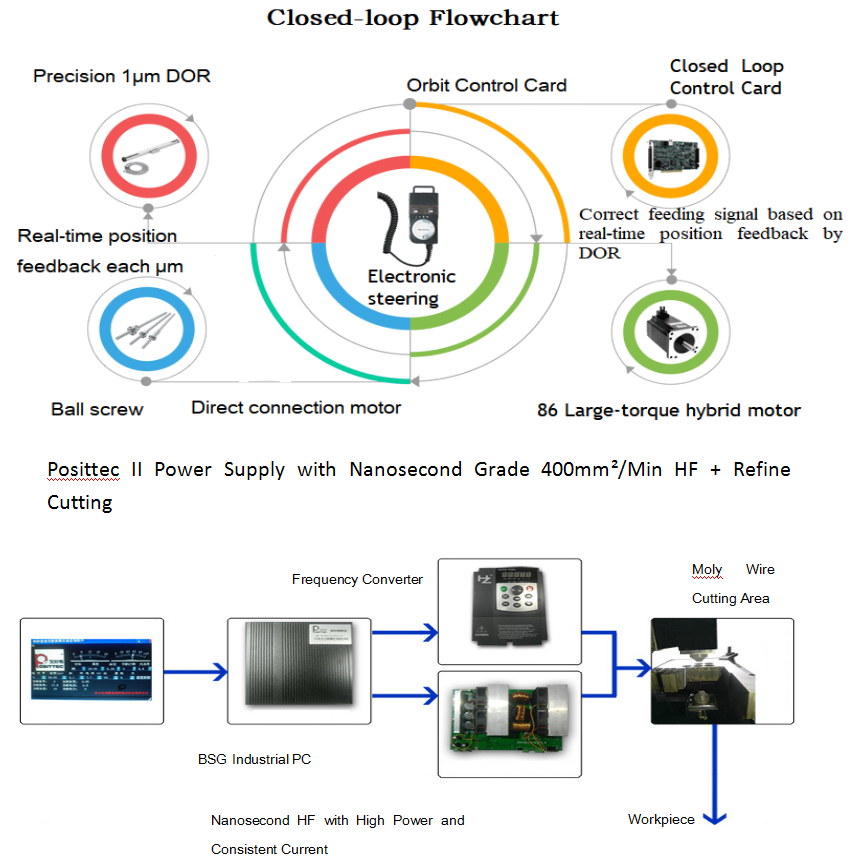

■Patent intelligent high frequency power. “Closed Loop Nanosecond Electroless HF Control System” is the only one in China. The min pulse width 7 nanosecond, electricity current controlled up to 0.01A and the single max current is 1600A.

■ “Closed Loop Track Control System”. Grating ruler with 1um resolution assists the Posittec BSG Nanosecond feeding system. Track control precision up to ±0.002mm.

■ “Wire Winding System without conductive block”. Conductive block removed from wire support frame and therefore it eliminates the friction between wire and conductive block. Hence no vibration or tension problem with wire and the winding is steadier and less wear out. Wire tension will be consistent from start to end.

Construction

· Resin cast machine body, steel HT250. Twice anneal for better durability.

· Main axis driven by hybrid motor.

· Equipped with BSGXP designing and controlling software, WINDOWS XP based system, Plug-in supported, can be integrated with most designing software.

· Data exchange and remote control supported.

· Accurate digital high frequency power, notch impulse, improves the cutting efficiency and reduces wire consumption.

· Power and driving system with patent makes it possible for high-speed cutting and revising.

· Newly designed control handle Electrical control handle makes it quick shift, position and speed changes.

· Unique design of Z axis without rail Up & down without steps. High precision positioning. Up & down easily in process without any impact or stop on performance.

· Unique water shelter design Nice looking and easy operation.

· X/Y equipped with super precision linear guide P3 grade high precision ball screw guide. Its precision is much higher than any other similar machines.

· Dual sides wire tensioner with consistent tension Keep the tension all the process. Complete prevent the poor roughness problem.

· Self-greasing system help you to save time for maintenance.

· The taper is equipment with stronger linear guide which makes the cutting more accurate and reliable.

· High pressure multi-screen system Designed with similar logic as slow speed WEDM. Three divisions in the water tank. Polluted water enters the first division for subside the third division. It separated the polluted water from the clean water. It saves water and environment.

· Water-proof guide wheel with patent design Easier wiring and consistent precision.

· Similar diamond guide as in slow speed WEDM Prevent wire from vibration.

· Wire drum is controlled with free of touch switches and AC frequency adaptor.

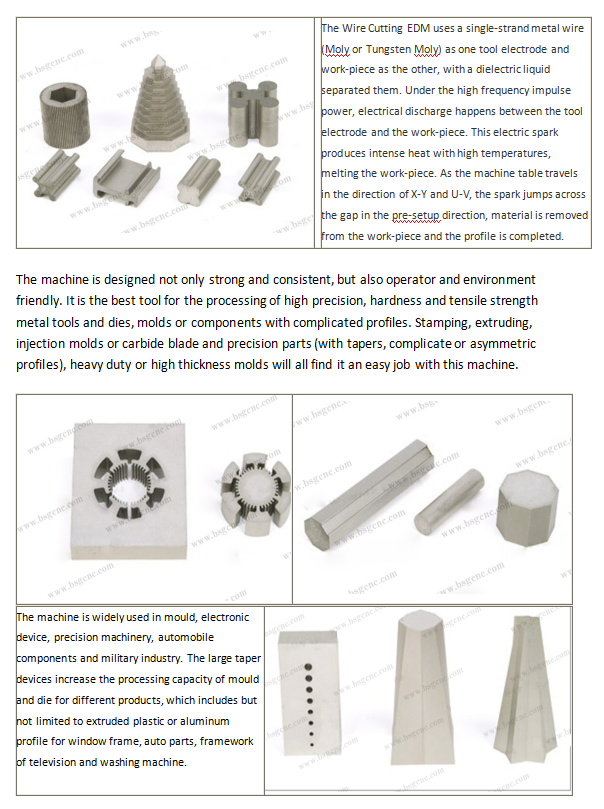

Application

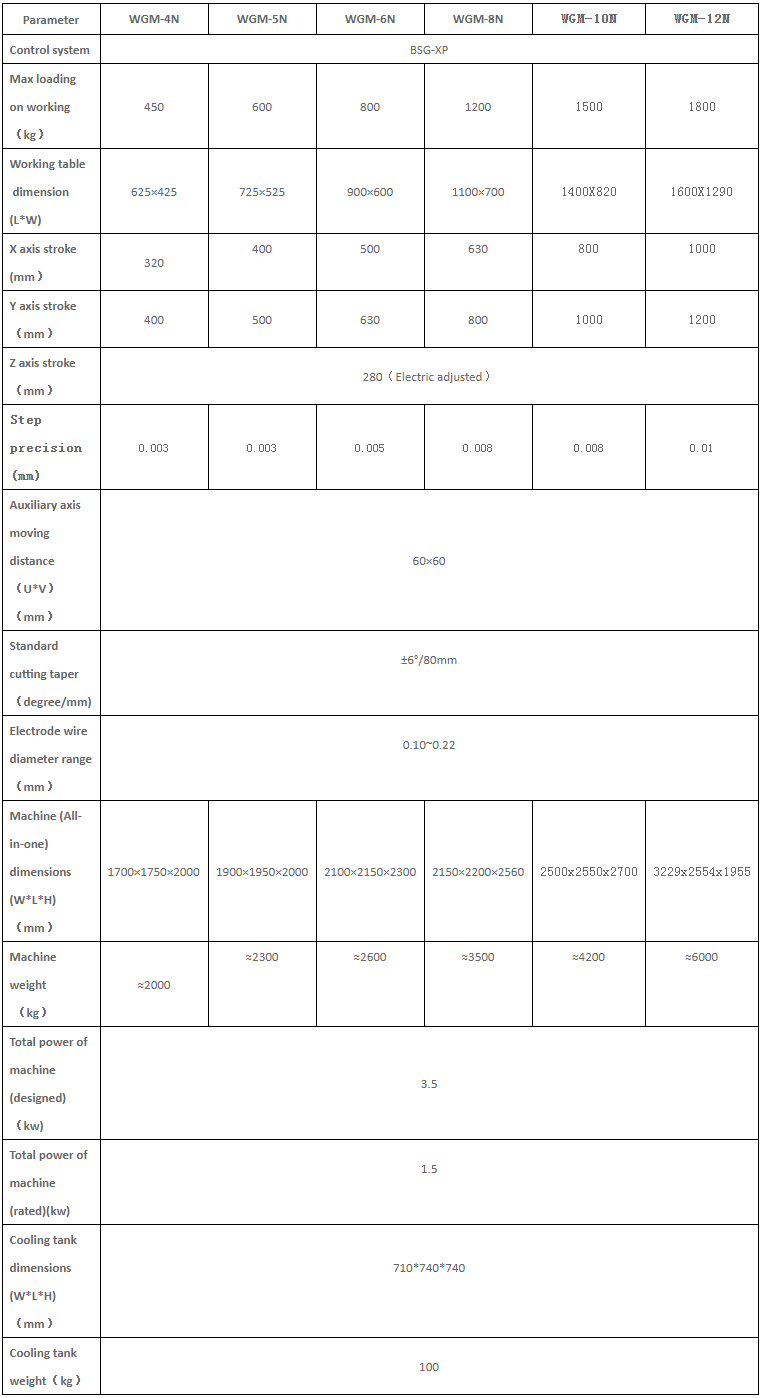

Key components & parameters

General Technical Parameters