Features

Standard Configuration

|  |

Application

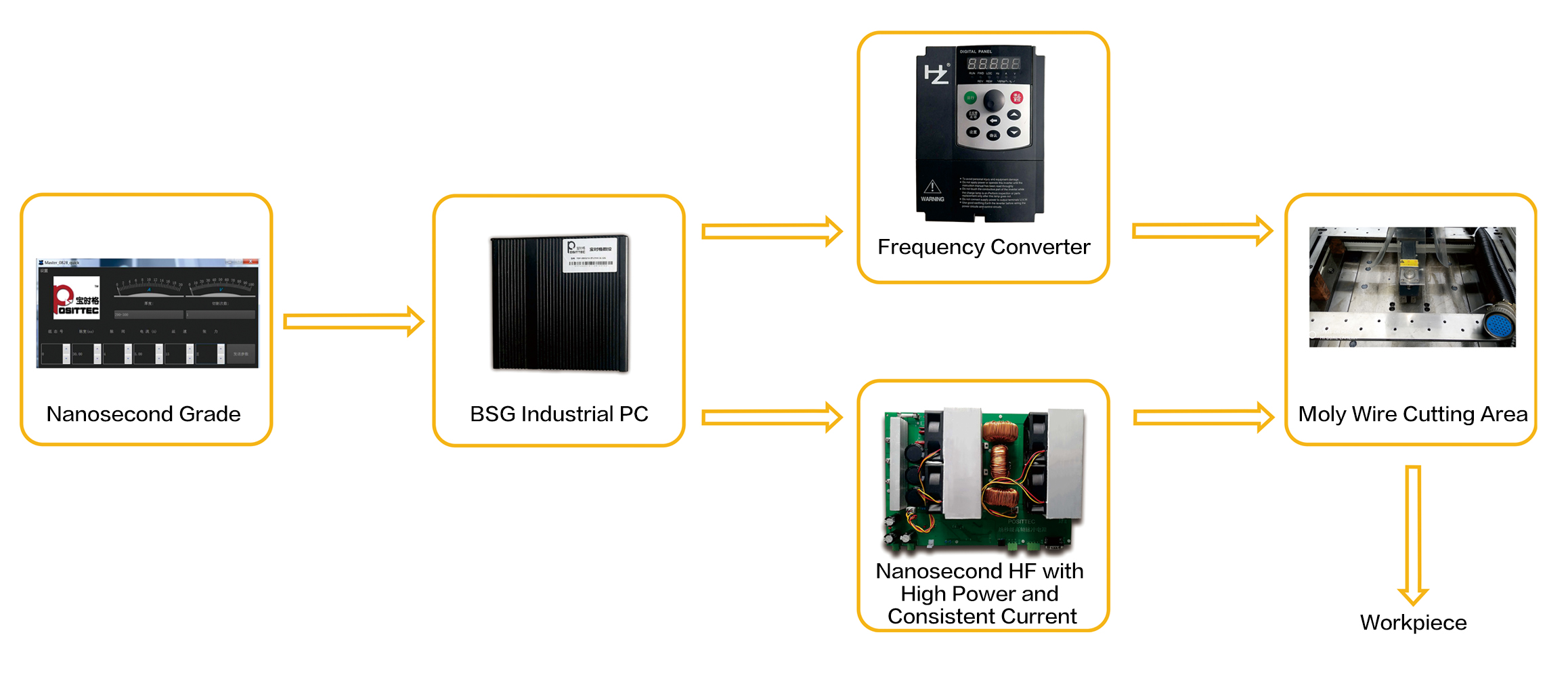

| The Wire Cutting EDM uses a single-strand metal wire (Moly or Tungsten Moly) as one tool electrode and work-piece as the other, with a dielectric liquid separated them. Under the high frequency impulse power, electrical discharge happens between the tool electrode and the work-piece. This electric spark produces intense heat with high temperatures, melting the work-piece. As the machine table travels in the direction of X-Y and U-V, the spark jumps across the gap in the pre-setup direction, material is removed from the work-piece and the profile is completed. |

The machine is well designed in with Ergonomics and modern construction. It is easy to be operated with super performance. The machine with stronger body and stability carries heavier work-piece. The lower cutting force and higher safety protection make the machine welcomed by operators. It can be used for any metal moulds, samples or parts with complicated profiles, which requires high precision, hardness and toughness. It is the best tool for the processing of stamping, extruding or injection mold, plastic mould, hob cutter, precision parts (including parts with big taper, equal or unequal taper, different profile upper and lower end), heavy load and thickness mould. | |

|  |

The machine is widely used in mould, electronic device, precision machinery, automobile components and military industry. The large taper devices increase the processing capacity of mould and die for different products, which includes but not limited to extruded plastic or aluminum profile for window frame, auto parts, framework of television and washing machine. |  |

Programming

INTELLIGENT BSGXP CONTROL SYSTEM

| BSGXP Intelligent software, which integrates the program and control and based on Windows XP. This new designed BSGXP software is the unique software for WEDM running on Windows XP. 1. Using the PCI slot controller card and the High-tech Industrial computer, which has increased the stability of control and reduced the computer failure rate. 2. To achieve a fast and convenient computer communication network, through network technology, graphics, data and program transmission, can be directly controlled by the technical design department since the first establishment of a program 3. Embedded Control system can be smoothly connected with many design software such as AUTOCAD & etc. 4. The search function of mechanical origin enable the transmission screw pitch compensation, in order to greatly improve the positioning accuracy, especially in Servo control system. 5. With a large storage capacity database, accumulated from many experiences. User can choose the suitable parameter according to deferent working conditions. Users can adjust machining parameters to establish a database at any time according to their own experience 6. The parameters of pulse power is directly controlled by the software , so as to not only improve anti-jamming capability in pulse power output, but also increase the roughness of work piece and reduce the loss of molybdenum wire . 7. Pulse power of the control parameters directly from the software to control and improve the ability of pulsed power output of the interference, thereby increasing the roughness of work piece, reducing the loss of molybdenum wire, you can choose a variety of pulse waveforms for a variety of processing conditions, improve the cutting ability of the work piece. BSGXP Software basic function 1. Coordinate system: absolute coordinate, incremental coordinate (relative coordinate) 2. Functions of coordinate transforming, zoom in and zoom out, rotating and tracking display in real time 3. Functions of interpolation of straight line and circular arc. 4. Function of taper processing 5. Function of processing different top and bottom shape 6. Functions of short circuit and wire-break handling 7. Functions of memorizing when power was cut and auto-stop after processing 8. Functions of auto-edge position and auto-centering 9. Function of auto-adding transitional arc (Arbitrary angle) 10. Function of processing backward 11. Functions of menu technology and auto-programming; 12. Data transmission functions of multi-cutting CNC System Configuration and Performances 1. CNC hardware 2. CNC software and operating platform: 3. CNC system technical performance: 4. CNC system working environment: |

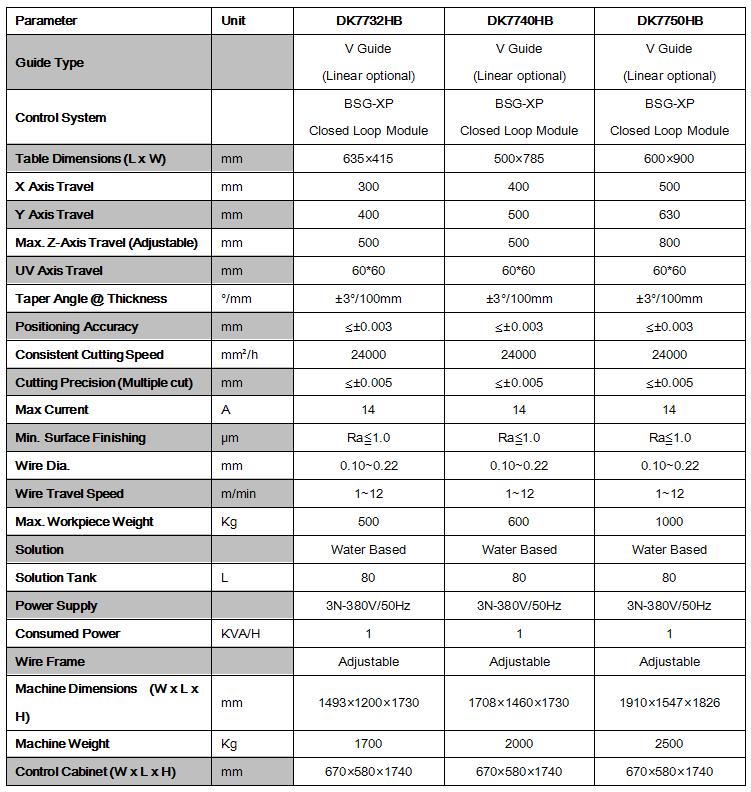

Parameters